OIML BULLETIN - VOLUME LXV - NUMBER 3 - JULY 2024

e v o l u t i o n s

The European single market for measuring instruments

Pavel Klenovský

Chairperson

Marc Wouters

Former Vice-Chair

WELMEC - the European Cooperation in Legal Metrology

1. Abstract

For over 50 years, the principle of free movement of goods has applied to measuring instruments within the European single market. This means that these instruments can be traded freely across borders without barriers arising from differing national legal metrology requirements.

For a vast number of measuring instrument categories, uniform essential requirements and harmonised standards ensure a high level of quality in measurement technology and reliability of measurement data. The single market creates a level playing field for manufacturers and distributors in the European Union (EU) and the European Economic Area (EEA), opening access to a vast market. At the same time, users have access to a broader range of instruments and see prices driven down by increased competition.

For the measuring instruments within the scope of current legislative acts, the technical and metrological performance requirements are almost fully in line with the corresponding OIML Recommendations.

While the single market for measuring instruments has brought significant benefits, it also faces challenges. These include the need to tackle legal metrology regulatory divergences regarding the enforcement of metrological control of measuring instruments in use and the increasing importance of reliable measurements in the policy areas of energy transition, climate change mitigation and circular economy.

Nevertheless, the European single market remains a cornerstone of international harmonisation of legal metrology procedures and standards in Europe and continues to support mutual confidence.

2. A brief history of harmonised legal metrology regulation in Europe

2.1 Directive 71/316/EEC

The first steps towards harmonising legal metrology practices in Europe resulted in the publication of Directive 71/316/EEC [1] on 26 July 1971. This directive addresses common provisions for measuring instruments and methods of metrological control. Its aim is to reduce trade barriers and create fairer competition by addressing discrepancies in national technical requirements and metrological control practices across European Economic Community (EEC) member states.

At the time, it became clear that notwithstanding the efforts for harmonisation of the legal metrology procedures of intergovernmental organisations such as the OIML, differences in national routines for metrological control effectively hinder trade and create unequal conditions of competition. Countries typically confirmed compliance with their own national technical requirements through pattern or type approval before allowing measuring instruments into their markets. Additionally, each instrument underwent initial verification by the legal metrology authority of the country in which it would be used. This created challenges for manufacturers, having to apply for type approval in each member state separately. It equally restricted the use of instruments verified in one country from being used in another.

Directive 71/316/EEC seeks to overcome these issues by establishing EEC pattern approval and initial verification procedures, along with mutual recognition of these controls by member states. The directive defines general rules and conditions for these procedures, while specific technical requirements and control procedures for different categories of measuring instruments are published in separate implementing directives.

Table 1 provides an overview of the various measurement instrument-specific directives published under the regulatory framework of Directive 71/316/EEC.

Table 1: Overview of measurement instrument-specific directives

|

Category of measuring instrument |

Directive |

Published on |

|

5 kg to 50 kg medium accuracy rectangular bar weights, |

71/317/EEC |

26 July 1971 |

|

Gas volume meters |

71/318/EEC |

26 July 1971 |

|

Meters for liquids other than water |

71/319/EEC |

26 July 1971 |

|

Standard mass per storage volume of grain |

71/347/EEC |

12 October 1971 |

|

Ancillary equipment for meters for liquids other than water |

71/348/EEC |

12 October 1971 |

|

Calibration of tanks of vessels |

71/349/EEC |

12 October 1971 |

|

Non-automatic weighing instruments (NAWI) |

73/360/EEC |

19 November 1973 |

|

Material measures of length |

73/362/EEC |

19 November 1973 |

|

Weights of from 1 mg to 50 kg of above-medium accuracy |

74/148/EEC |

4 March 1974 |

|

Cold water meters |

75/33/EEC |

17 December 1974 |

|

Prepackaged liquids |

75/106/EEC |

19 December 1974 |

|

Continuous totalizing weighing machines |

75/410/EEC |

24 June 1975 |

|

Prepackaged products |

76/211/EEC |

20 January 1976 |

|

Clinical mercury in glass thermometers |

76/764/EEC |

27 July 1976 |

|

Alcoholmeters and alcohol hydrometers |

76/765/EEC |

27 July 1976 |

|

Alcohol tables |

76/766/EEC |

27 July 1976 |

|

Electrical energy meters |

76/891/EEC |

4 November 1976 |

|

Taximeters |

77/95/EEC |

21 December 1976 |

|

Measuring systems for liquids other than water |

77/313/EEC |

5 April 1977 |

|

Automatic checkweighing and weight grading machines |

78/1031/EEC |

5 December 1978 |

|

Hot water meters |

79/830/EEC |

11 September 1979 |

|

Nominal capacities permitted for prepackaged products |

80/232/EEC |

15 January 1980 |

|

Tyre pressure gauges for motor vehicles |

86/217/EEC |

26 May 1986 |

2.2 Leading principles of the 1971 directive

The 1971 directive establishes key principles for EEC type approval and initial verification, including:

- Technical requirements for metrological performance, maximum permissible errors, and measurement reliability are detailed in specific directives.

- Each member state with the necessary technical and organisational means is required to offer EEC type approval services. For the same instrument (type), application may be made in one member state only.

- When an instrument has successfully completed the EEC type approval examination, the member state that conducted the examination shall draw up an EEC type approval certificate. The applicant must affix the EEC approval mark on each instrument that conforms to the approved pattern. EEC type approval is valid for 10 years, with the possibility of extension.

- EEC initial verification assesses compliance with the applicable requirements and, in cases of EEC type approval, conformity with the approved pattern. On successful completion, the EEC verification marking is affixed to the instrument. In principle, an initial verification is valid until the end of the year following the date of verification.

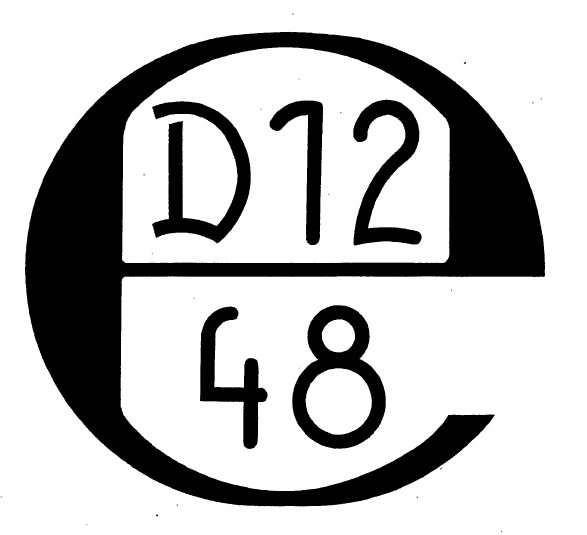

(a)

(b)

(c)

Figure 1:

(a) Example of EEC type approval marking, granted by the German metrological authority in 1971, with a space (….) for the EEC type approval identification number.

(b) Example of the first part of the EEC verification marking identifying (in the upper half of the letter “e”) the member state together with, where necessary, the figures identifying the administrative subdivision, and (in the lower half of the letter “e”) the identification number of the verifying agent or office.

(c) Example of the second part of the EEC verification marking: the last two digits of the year of the verification, in a hexagon.

2.3 Significance of the 1971 directive

With the directive in effect, member states could no longer prohibit or restrict the market placement or entry into service of measuring instruments bearing the EEC initial verification or EEC type approval marking (see Figure 1 for an example). This establishes the principle of mutual recognition, where EEC type approval and initial verification in another member state are equivalent to corresponding national measures.

The directive also establishes an overall concept primarily consisting of four elements:

- Essential requirements for metrological performance and suitability/reliability of measurements for regulated use, apply equally in all member states.

- Type approval procedures to attest conformity of instrument design.

- Initial verification to confirm compliance before instruments are put into use.

- Market surveillance by member states to ensure compliance with regulatory requirements.

These measures aim to create a harmonised set of provisions for metrological control across the EEC. As a general rule, for measuring instruments within the scope of the regulation, the corresponding national measures were to be abolished.

Recognising the need to stay abreast of technological advancements and foster innovation, the directive established a Measuring Instrument Committee. This committee, led by the European Commission and comprising legal metrology representatives from member states, was empowered to propose technical amendments to the instrument-specific directives. This forward-thinking provision allowed the regulatory framework to remain relevant and responsive to evolving technologies.

It is worth noting that in the same period, a directive [2] was published to harmonise the laws regulating the use of units of measurement in the member states to ensure that their names, symbols, and use are consistent in all member states.

2.4 Evolution over time, introducing the “new approach”

When Directive 71/316/EEC was first implemented, the European Economic Community (EEC) consisted of only six founding members [3]. As the EEC evolved into the European Union (EU) with an increasing number of member states, the legislation needed to adapt.

Establishing a European single market for goods, with the free movement of goods as a cornerstone, has been a central objective of international cooperation in Europe from the outset. Directive 71/316/EEC represented an initial effort towards this goal in the realm of legal metrology, with similar initiatives implemented for other products.

However, it quickly became evident that the existing approach of incorporating detailed technical requirements directly into legislation is unwieldy and poses a significant obstacle to innovation. The rigidity of these detailed specifications hinders the adaptability of regulations to keep pace with technological advancements. To address this, the EEC, which had expanded to twelve members, introduced the "new approach" in 1985.

This new approach marks a radical shift in how harmonised standards are utilised in regulatory contexts. Its primary aim is to streamline technical harmonisation and further dismantle technical barriers to trade within the internal market. By focusing on defining broad, performance-based essential requirements for products, rather than rigid technical specifications, the new approach fosters technological innovation and flexibility.

In parallel, the new approach actively encourages the development and adoption of harmonised European standards (ENs) as a means of demonstrating conformity with these essential requirements. Products adhering to these standards are presumed to meet the necessary criteria, thereby facilitating their access to the market and promoting the unhindered flow of goods across borders.

The new approach also introduces a modular system of conformity assessment procedures, allowing manufacturers to choose the most appropriate procedure based on the risk level of their product. The CE marking emerges as a visible symbol of this conformity, providing a clear indication that a product meets the essential requirements of the relevant directives and can thus move freely within the EU and the EEA.

National authorities within member states are responsible for market surveillance to ensure that only compliant products are placed on the market and/or put into use. This involves verifying product compliance with the essential requirements, checking correct markings and availability of required user information, and taking appropriate action against non-compliant products.

2.5 Adapting the 1971 directive to the “new approach”

The legal metrology regulatory framework was subsequently adapted to align with the philosophy of the new approach. This led first to the publication of the Non-Automatic Weighing Instruments Directive (NAWID) 90/384/EEC [4] in 1990. In 2004, the Measuring Instruments Directive (MID) 2004/22/EC [5] was published, followed by the recodification of the Non-Automatic Weighing Instruments Directive (NAWID) 2009/23/EC [6] in 2009, which introduced new provisions on the use of harmonised standards, conformity assessment, and market surveillance. Soon after the publication of these directives, the previously existing directives were all repealed and no longer affect the marketing and use of measuring instruments.

Coinciding with the adoption of the first “new approach” metrology directive in Europe in 1990, on which the legal metrology authorities of the member states had worked closely together, WELMEC [7] was created as the regional legal metrology organisation. From that moment forward WELMEC has actively promoted cooperation between member states and interacted with the European Commission and stakeholders.

While the primary intent of the initial directive of 1971 is consumer protection, in other words, to give assurance to customers that quantities delivered correspond to prices paid, when the 2004 and 2009 directives were adopted, it was generally recognised that reliable and traceable measurement is also supportive of the objectives of other policy fields that directly and indirectly affect the daily life of citizens. For that reason, the mandatory use of legally controlled measuring instruments is extended to measurements for reasons of public interest, public health, safety and order, protection of the environment and the consumer, of levying taxes and duties, and of fair trading. At the same time, the focus shifted from harmonising legal metrology control practices to facilitating the free movement of measuring instruments within the European market. The scope also changed, with some instrument types no longer included in Directive 2009/23/EC.

2.6 Legal metrology directives in force today

The current legal metrology directives, the Measuring Instruments Directive (MID) 2014/32/EU [8] and the Non-Automatic Weighing Instruments Directive (NAWID) 2014/31/EU [9], were adopted in 2014 as recasts of the 2004 and 2009 directives.

These directives retain the key elements of the 1971 regulation while incorporating the principles of the new approach. They include common essential performance requirements for metrological accuracy and reliability and the application of the “New Legislative Framework” relative to third-party conformity assessment and market surveillance.

The MID and NAWID aim to provide a high level of confidence for consumers, end-users, economic operators, and authorities who rely on trustworthy measurement results. They provide a framework for ensuring the free movement of compliant measuring instruments within the European single market while upholding essential requirements for performance and reliability.

Although legal metrological control of measurements is recognised in various fields, member states still have the autonomy to decide whether to regulate the use of metrologically controlled instruments. Where such control is specified, only measuring instruments complying with the MID or the NAWID are allowed to be used.

The Measuring Instruments Directive (MID) 2014/32/EU and the non-automatic weighing instruments directive 2014/31/EU (NAWID) are explained in more detail below.

3. The Measuring Instruments Directive (MID)

The Measuring Instruments Directive (MID) 2014/32/EU, adopted in February 2014, constitutes the current regulatory framework for marketing measuring instruments in the EU and the EEA. A recast of the 2004 MID, this directive retains most technical and performance requirements for the instruments covered while refining the provisions on conformity assessment, market surveillance, and administrative obligations for manufacturers, importers, and distributors. The MID harmonises the rules for placing measuring instruments on the market, ensuring their accuracy, reliability, and compliance with essential requirements before putting them into use.

Regarding the type approval and initial verification of measuring instruments, the general principles and rules of mutual recognition by member states, as envisaged in the 1971 regulatory act, are broadly maintained. These principles are integrated into a modern legislative framework and adapted to the current economic landscape.

3.1 Structure of the MID

The MID is structured into chapters and annexes, covering general provisions, obligations of economic operators, conformity assessment procedures, notification of conformity assessment bodies, market surveillance, and more. Annex I defines essential requirements applicable to all measuring instruments, while Annexes III to XII detail specific requirements for different instrument categories.

Table 2: Contents and structure of the Measuring Instruments directive (2014/32/EU).

|

Part |

Title / Subject |

Article |

|

|

Preamble |

|

|

Preamble |

Introductory considerations |

|

|

|

Main body |

|

|

Chapter 1 |

General provisions |

1 - 7 |

|

Chapter 2 |

Obligations of economic operators |

8 – 13 |

|

Chapter 3 |

Conformity of measuring instruments |

14 – 22 |

|

Chapter 4 |

Notification of conformity assessment bodies |

23 – 40 |

|

Chapter 5 |

Union market surveillance, control of measuring instruments entering the Union market and Union safeguard procedure |

41 – 45 |

|

Chapter 6 |

Committee and delegated acts |

46 – 48 |

|

Chapter 7 |

Transitional and final provisions |

49 – 54 |

|

|

Annexes |

|

|

Annex I |

Essential requirements |

|

|

Annex II |

Conformity assessment procedures |

|

|

Annex III |

Water meters (MI-001) |

|

|

Annex IV |

Gas meters and volume conversion devices (MI-002) |

|

|

Annex V |

Active electrical energy meters (MI-003) |

|

|

Annex VI |

Thermal energy meters (MI-004) |

|

|

Annex VII |

Measuring systems for the continuous and dynamic measurement of quantities of liquids other than water (MI-005) |

|

|

Annex VIII |

Automatic weighing instruments (MI-006) |

|

|

Annex IX |

Taximeters (MI-007) |

|

|

Annex X |

Material measures (MI-008) |

|

|

Annex XI |

Dimensional measuring instruments (MI-009) |

|

|

Annex XII |

Exhaust gas analysers (MI-010) |

|

|

Annex XIII |

EU Declaration of conformity (model) |

|

|

|

Regulatory continuity |

|

|

Annex XIV |

Repealed Directives and dates of application |

|

|

Annex XV |

Correlation table with Directive 2004/22/EC |

|

3.2 Scope of the MID

The scope of the MID is limited to the types of measuring instruments specified in Annexes III to XII. A detailed list can be found in Table 2.

However, the classification of instruments goes beyond simply the measurand (the quantity being measured). The instrument-specific annexes define categories not only by the measurand but also by the object carrying the quantity (e.g., water meters measure volumes of clean, cold or heated water) and the context of the measurement (e.g., intended for residential, commercial, or light industrial use).

Furthermore, the MID’s scope considers the measurement task itself. Member states can prescribe the use of metrologically controlled instruments not just for consumer protection, but also for a wide range of public interests including public health, safety, environmental protection, taxation, and fair trading.

In essence, any measuring instrument falling under the categories specified in the annexes and intended for a regulated measurement task must comply with the MID’s requirements before being placed on the market or put into use. This comprehensive approach ensures that the MID covers a wide array of instruments used in diverse contexts, reflecting the multi-faceted role of measurement in modern society.

3.3 Essential requirements (Annex I)

The essential requirements outlined in Annex I form the foundation of the MID, applying to all measuring instruments regardless of their specific type. They ensure fundamental aspects of performance and functionality.

The MID mandates that instruments provide accurate and reliable measurements. This entails several key aspects of metrological performance and covers the accuracy, repeatability, stability, and sensitivity of the instrument over a specified measuring range. These aspects must be in line with the intended measurement task and proportionate to the maximum permissible error (MPE) further specified in the instrument-specific annexes.

External factors such as temperature, humidity, pressure, and electromagnetic interference can affect measurement accuracy. Instruments must be designed to minimise the influence of these factors and provide accurate results within specified environmental and mechanical conditions. The influence factors must be considered during conformity assessment.

The directive also establishes different classes for mechanical and electromagnetic environments, allowing member states to specify, if needed, the applicable class for regulated measurement tasks.

Software embedded in measuring instruments must be developed to support accurate and reliable measurements. It should be verifiable, meaning its correct operation can be checked, and protected against unauthorised modification that could compromise performance. Distinction between metrologically relevant software and other software components is optional.

The resulting indication shall be clear and unambiguous and, for measuring instruments used for direct sales, easily accessible and understandable for consumers. Whether or not an instrument intended for measuring provided utility services can be remotely read, it shall, in any case, be equipped with a metrologically controlled display that is accessible to consumers without the use of tools.

All measuring instruments shall be protected against misuse. The design and production must minimise the risk of misuse, whether intentional or unintentional, and fraudulent use.

Annex I also defines the information that must be displayed on the instrument (manufacturer’s information, accuracy, measuring capacity, etc.) and the mandatory accompanying documentation (rated operating conditions, installation instructions, compatibility with interfaces and sub-assemblies, etc.).

3.4 Instrument-specific requirements (Annexes III to XII)

The instrument-specific annexes build upon the general requirements and provide detailed specifications tailored to individual instrument categories. Each annex begins by clearly defining the specific category of measuring instruments it covers. These definitions often consider not just the measurand but also the intended application and usage context.

Each annex specifies the MPEs for the instrument category, defining the acceptable limits of measurement deviation. These MPEs are crucial for ensuring fair trade and consumer protection.

The annexes provide guidance on determining the suitability of instruments for specific applications and defining their rated operating conditions. This helps ensure that instruments are used appropriately and perform reliably in their expected environments. Hence, specific testing and verification guidance for each instrument category are outlined. These elements need to be considered during conformity assessment to ensure that instruments meet their declared performance specifications.

Each annex details the conformity assessment procedures eligible for the specific instrument category.

3.5 Manufacturers’ responsibility and obligations

Manufacturers bear the primary responsibility for ensuring that their measuring instruments comply with the MID. This includes designing, developing, and producing instruments that meet the essential and relevant instrument-specific requirements. Before placing a measuring instrument on the EU market, manufacturers must demonstrate conformity. Conformity assessment procedures, detailed in Annex II, ensure that measuring instruments meet the requirements of the MID. These procedures include design examination, type examination, and initial verification through production control or individual inspection, but can vary in stringency depending on the instrument’s risk level and complexity. In most cases, they involve notified bodies, which are third-party conformity assessment bodies authorised to assess conformity.

By adhering to harmonised standards for the MID [10] or OIML Recommendations [11], the manufacturer benefits from a presumption of conformity with the MID requirements covered by those documents. This means that instruments are considered to be compliant with the relevant aspects of the MID, streamlining their development and progress through the conformity assessment process.

WELMEC – the European Cooperation in Legal Metrology – has published on its website [12] a series of non-legally binding guidance documents supporting consistent implementation of essential requirements.

Once compliance is demonstrated, manufacturers issue an EU declaration of conformity and affix the CE marking along with the supplementary metrology marking (see Figure 2) to each instrument. They must also provide clear instructions for use.

Figure 2: Example of CE marking and supplementary metrology marking for measuring instruments

Manufactures shall, upon a motivated request, cooperate with the national market surveillance authorities.

3.6 Obligations for economic operators, other than the manufacturer

Economic operators defined in the MID concern manufacturers, importers, and distributors of measuring instruments, and, optionally, authorised representatives of the manufacturer.

Manufacturers may designate an authorised representative established within the EU to handle certain obligations, such as preserving the EU declaration of conformity or acting as a contact point for market surveillance.

An importer, as defined within the EU, is the actor who places a measuring instrument from outside the EU on the single European market. The importer shall primarily ensure that the appropriate conformity assessment procedure has been conducted by the manufacturer and that the measuring instrument bears the CE marking and the supplementary metrology marking and is accompanied by a copy of the EU declaration of conformity and the required documents. Importers shall indicate on the measuring instrument or on the accompanying documentation and packaging their name or trademark and the postal address at which they can be contacted.

Each other actor in the measuring instruments’ supply chain is considered to be a distributor. Before placing a measuring instrument of the market and/or putting it into use, the distributor shall verify that the instruments bear the required markings and are accompanied by the required documents.

Importers and distributors must ensure that compliance is not jeopardised during transport or storage. They must take corrective actions if non-compliance is suspected and cooperate with market surveillance authorities.

3.7 Notified bodies

Notified bodies are a critical component of the MID’s conformity assessment infrastructure. They provide an independent and impartial assessment of measuring instruments.

Notified bodies are organisations designated by member states and officially notified to the European Commission for recognition to perform the conformity activities for which they are evaluated as competent by the notifying authority of that member state. The notifying authority is responsible for the evaluation and monitoring of notified bodies. For these latter tasks, it may rely on accreditation of the conformity assessment body.

Notified bodies must meet stringent criteria relating to the impartiality, competence and consistency of their assessments.

Notified bodies perform a variety of conformity assessment tasks under the MID, depending on the specific instrument category and chosen conformity assessment module. These tasks can include:

- EU type examination: Evaluating the design of a measuring instrument to ensure it meets the essential requirements.

- EU design examination: Assessing the design of a measuring instrument with a focus on its suitability for specific applications.

- Individual or statistical inspection: Examining and testing individual instruments to verify their conformity with the approved type or design.

- Quality assurance: Assessing and certifying the manufacturer’s quality management system to ensure consistent production of compliant instruments.

The European Commission maintains a publicly accessible database of notified bodies under the NANDO [13] (New Approach Notified and Designated Organisations) information system. This ensures transparency and allows manufacturers and other stakeholders to easily identify notified bodies that are qualified to assess their specific instrument types.

Notified bodies are also expected to cooperate with each other and with market surveillance authorities to ensure consistent application of the MID and share information on conformity assessment issues. Currently, a coordinating role is attributed to NoBoMet; the European coordination group for notified bodies in legal metrology [14].

3.8 Obligations for EU member states

The MID places several obligations on EU member states, focusing on ensuring the harmonised implementation of the directive and maintaining effective market surveillance to guarantee the quality and accuracy of measuring instruments and the reliability of measurement results.

A cornerstone principle of the MID is the mutual recognition of measuring instruments. This means that a measuring instrument lawfully marketed in one EU member state can be freely sold and used in any other member state without additional requirements or restrictions. Member states are obligated to respect this principle and cannot impose any additional national rules that would hinder the free movement of compliant instruments.

Member states are responsible for establishing and maintaining comprehensive market surveillance schemes. These schemes aim to ensure that only measuring instruments complying with the MID are made available on the market and put into use. Market surveillance authorities conduct various activities, including:

- Checking conformity: Verifying that instruments bear the required markings (CE marking and supplementary metrology marking) and are accompanied by the necessary documentation.

- Testing and inspection: Conducting random checks and inspections of instruments to ensure they meet the essential requirements and relevant instrument-specific requirements.

- Investigating complaints: Responding to complaints from consumers, businesses, or other stakeholders regarding potentially non-compliant instruments.

- Taking corrective action: Requiring economic operators (manufacturers, importers, distributors) to take corrective actions, such as withdrawing or recalling non-compliant instruments from the market.

- Cooperation: Collaborating with other member states and the European Commission to exchange information and coordinate market surveillance activities.

3.9 Union safeguard procedure: a balancing mechanism

The Union safeguard procedure is a critical mechanism that ensures the harmonious application of the MID across the EU. It acts as a safety net for both member states and economic operators, ensuring that market surveillance actions are justified and proportionate.

If a member state’s market surveillance authority identifies a non-compliant measuring instrument, it can take corrective actions, such as requiring the economic operator to rectify the issue, withdraw the instrument from the market, or perform a recall. However, this authority is not absolute. If an economic operator believes these actions are unjustified, or if another member state deems the measures disproportionate, the Union safeguard procedure is activated.

This procedure triggers a consultation involving all member states and relevant economic operators, under the direction of the European Commission. This consultative process aims to assess the situation objectively and reach a consensus on the appropriate course of action. The European Commission ultimately decides whether the national measure is justified, ensuring a balanced and fair outcome.

In essence, the Union safeguard procedure serves two vital purposes:

- Protection for member states: It empowers market surveillance authorities to take necessary action against non-compliant instruments, ensuring the reliability and accuracy of measurements within their territories.

- Protection for economic operators: It provides a recourse mechanism for economic operators who feel they have been subjected to unjustified or disproportionate measures by a national authority.

4. The Non-Automatic Weighing Instruments Directive (NAWID)

The Non-Automatic Weighing Instruments Directive (NAWID) 2014/31/EU, adopted in February 2014, serves as the current regulatory framework for marketing non-automatic weighing instruments in the EU and the EEA. This directive is a recast of the 2009 NAWID and essentially maintains technical and performance requirements for weighing instruments while amending and clarifying provisions on conformity assessment, market surveillance, and administrative obligations.

Table 3: Contents and structure of the Non-Automatic Weighing Instruments Directive (2014/31/EU)

|

Part |

Title / Subject |

Article |

|

|

Preamble |

|

|

Preamble |

Introductory considerations |

|

|

|

Main body |

|

|

Chapter 1 |

General provisions |

1 - 5 |

|

Chapter 2 |

Obligations of economic operators |

6 – 11 |

|

Chapter 3 |

Conformity of instruments |

12 – 18 |

|

Chapter 4 |

Notification of conformity assessment bodies |

19 – 35 |

|

Chapter 5 |

Union market surveillance, control of instruments entering the Union market and Union safeguard procedure |

36 – 40 |

|

Chapter 6 |

Committee, transitional and final provisions |

41 – 47 |

|

|

Annexes |

|

|

Annex I |

Essential requirements |

|

|

Annex II |

Conformity assessment procedures |

|

|

Annex III |

Inscriptions |

|

|

Annex IV |

EU Declaration of conformity (model) |

|

|

|

Regulatory continuity |

|

|

Annex V |

Repealed Directives and dates of application |

|

|

Annex XV |

Correlation table with Directive 2009/23/EC |

|

4.1 Similarities and differences between NAWID and MID

The general structure and principles of the NAWID closely mirror those of the Measuring Instruments Directive (MID). However, a key distinction is that the NAWID applies to all non-automatic weighing instruments, regardless of their intended use.

4.2 Scope of the NAWID

A non-automatic weighing instrument, as defined by the NAWID, is one that requires operator intervention during weighing. Article 1(2) of the directive defines various measurement use cases, all considered regulated weighing tasks and subject to legal metrological control. These include determining mass for 1) commercial transactions, 2) calculating tolls, tax, penalties or similar payments, 3) applying laws, 4) practicing medicine, 5) preparing medicines and medical analysis, and 6) determining prices for direct sales or prepackages.

All other applications are considered non-regulated measurement tasks. While the NAWID applies to the marketing of all non-automatic weighing instruments, only those intended for regulated tasks must comply with the essential requirements outlined in Annex I.

Non-automatic weighing instruments not intended for regulated tasks may not bear the CE marking or other conformity markings.

4.3 Essential requirements

Annex I defines the essential requirements for non-automatic weighing instruments intended for regulated weighing tasks. These focus on ensuring accurate and reliable measurements, covering aspects such as accuracy, stability, and durability. The NAWID defines four accuracy classes: special (I), high (II), medium (III), and ordinary (IIII).

The NAWID also includes specific requirements regarding verification scale intervals, multi-interval instruments, and maximum permissible errors (MPEs).

Design and construction must consider operating conditions and minimise the impact of external factors on measurement accuracy. Special attention is given to indication and printing functionalities, as well as protection against misuse and fraud.

Further to the essential requirements in Annex I, Annex III of the NAWID details mandatory inscriptions for clarifying measurement conditions and limits of use.

4.4 Obligations for economic operators

Obligations for manufacturers, importers, and distributors under the NAWID are largely equivalent to those under the MID. However, a key difference is that only harmonised standards, not OIML Recommendations, are used to grant presumption of conformity for non-automatic weighing instruments [15].

Non-automatic weighing instruments intended for regulated weighing tasks can only be put into service if they meet the NAWID’s essential requirements. Manufacturers must engage in conformity assessment processes involving notified bodies to demonstrate compliance. These procedures typically include type or design approval and initial verification.

After demonstrating compliance, manufacturers issue an EU declaration of conformity and affix the CE marking and supplementary metrology marking (see Figure 2) to each instrument. All non-automatic weighing instruments placed on the market and intended for regulated weighing tasks must be accompanied by the EU declaration of conformity and instructions for proper use. Compliant instruments benefit from mutual recognition across the EU and the EEA.

Non-automatic weighing instruments not intended for regulated tasks may not bear the CE marking or other conformity markings.

4.5 Notified bodies, member state obligations, and the safeguard procedure

The provisions regarding notified bodies, member state obligations, and the Union safeguard procedure are analogous to those under the MID.

4.6 Restrictive use symbol

The NAWID introduces a specific restrictive use symbol. Where an instrument which is intended to be used for any of the regulated weighing tasks mentioned above is connected to a device that is not intended for such a regulated weighing task, the manufacturer must apply the restrictive use symbol to this device. The restrictive use symbol consists of a capital "M" in a red square with a cross.

5. Present situation and future challenges

The current regulations governing the marketing of measuring instruments and non-automatic weighing instruments are the culmination of ongoing efforts to harmonise the European single market, enabling the free movement of goods within the EU and the EEA. By combining essential requirements with harmonised standards and the relevant OIML Recommendations, these directives provide a comprehensive yet adaptable framework, ensuring the accuracy and reliability of measuring instruments across a wide array of applications. This approach balances the necessity of harmonisation and consumer protection with the flexibility needed to adapt to technological advancements and diverse measurement needs.

Notified bodies are a critical component of the directives’ conformity assessment infrastructure. They provide an independent assessment of measuring instruments, safeguarding against low-quality products and ensuring that only compliant products are placed on the market and put into service. By entrusting conformity assessment to qualified and impartial bodies, the directives strike a balance between regulatory oversight and market flexibility, fostering innovation while upholding essential standards for measurement accuracy and reliability.

The active participation of member states, facilitated by WELMEC is also essential for achieving the directives’ objectives. Through robust market surveillance and cooperation, they contribute to a harmonised and trustworthy measurement landscape across the EU and the EEA, safeguarding both end-user protection and the free movement of compliant instruments.

It is important to note that the scope of the MID and NAWID extends well beyond consumer protection, recognising the significance of accurate and reliable measurement in diverse policy areas such as public health, public safety, environmental protection, taxation, and fair trading. This broader scope reflects the vital role of measurement in modern society.

However, as societal and economic contexts evolve, the legal metrology landscape must also adapt. Two significant challenges currently occupy legal metrology offices in member states:

- Adapting to evolving needs: The essential and instrument-specific requirements established in the late 20th century may not fully address the specific measurement tasks arising in areas such as energy transition, climate change mitigation, and the circular economy. For example, debates relating to legal metrology controls for electric vehicle charging stations and relating to the need for authoritative supervision of centralised, online, near-real-time indications for utility meters, are still ongoing.

- Harmonising in-use controls: Discrepancies in national rules regarding subsequent verification of instruments in use can hinder the free movement of services. In some cases, a subsequent verification marking applied in one country may not be recognised by another, creating barriers to cross-border services. Organisations are urging the European Commission to address these inconsistencies and further harmonise in-use legal metrological controls.

The continuous efforts of all WELMEC members to support and harmonise legal metrology practices are crucial for maintaining trust in measurement results, protecting consumers and end-users, and ensuring fair competition. By proactively addressing these challenges, Europe can continue to foster a robust and adaptable legal metrology framework that meets the evolving needs of society and the economy.

[1] Council Directive of 26 July 1971 on the approximation of the laws of the Member States relating to common provisions for both measuring instruments and methods of metrological control (71/316/EEC).

[2] Council Directive 71/354/EEC of 18 October 1971 on the approximation of the laws of the Member States relating to units of measurement.

[3] Building on the success of the Coal and Steel Treaty (1951), the 6 founding countries (Germany, France, Italy, the Netherlands, Belgium and Luxemburg) expand their cooperation to other economic sectors, by signing, in 1957, two treaties, creating the European Economic Community (EEC), and the European Atomic Energy Community (Euratom).

[4] Council Directive 90/384/EEC of 20 June 1990 on the harmonisation of the laws of the Member States relating to non-automatic weighing instruments.

[5] Directive 2004/22/EC of the European Parliament and of the Council of 31 March 2004 on measuring instruments.

[6] Directive 2009/23/EC of the European Parliament and of the Council of 23 April 2009 on non-automatic weighing instruments.

[8] Directive 2014/32/EU of the European Parliament and of the council of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of measuring instruments (recast).

[9] Directive 2014/31/EU of the European Parliament and of the council of 26 February 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of non-automatic weighing instruments (recast).

[10] A list of harmonised standards for the MID can be found on the European Commission’s website:

https://single-market-economy.ec.europa.eu/single-market/european-standards/harmonised-standards/measuring-instruments-mid_en

[11] A link to the OIML Recommendations formally recognised as normative documents with presumption of conformity to the MID, and the associated corresponding table, can be found on the European Commission’s website:

https://single-market-economy.ec.europa.eu/single-market/goods/building-blocks/legal-metrology/measuring-instruments_en

[12] https://www.welmec.org/guides-and-publications/guides

[13] https://webgate.ec.europa.eu/single-market-compliance-space/#/notified-bodies

[15] The sole harmonised standard referenced for the NAWID is EN 45501:2015 “Metrological aspects of non-automatic weighing instruments”. This standard has been adapted from the OIML Recommendation R 76-1, Edition 2006.