OIML BULLETIN - VOLUME LXV - NUMBER 4 - October 2024

t e c h n i q u e

LNG measurement

Towards harmonized mass and volume measurements for LNG custody transfer

Menne Schakel and Erik Smits

VSL, Thijsseweg 11, 2629 JA, Delft, The Netherlands

Abstract

Over the past decades the liquefied natural gas (LNG) industry has grown at a steady, strong rate. Measurement capabilities have evolved as technologies have matured alongside the take-up of LNG as a significant component in the energy mix.

At large scale (un)loading of LNG carriers at export or import terminals, the customary practice of LNG custody transfer is based on the determination of the carriers’ cargo tank volume and the measurement of the LNG composition. At small scale, where LNG is used as a transportation fuel, the custody transfer is typically based on the amount of transferred mass. With the LNG measurement capabilities that are currently available, including the traceability to the SI units of measurement, it is possible to significantly improve custody transfer measurements.

By upgrading small scale measurement capabilities to large scale capabilities, an independent measurement methodology based on mass can be harmonized with the customary measurement practice based on the carriers’ tank volume. In a similar fashion, large scale volume measurements can be downscaled to small scale mass-based measurement methods. Thus, harmonization of mass and volume measurements for LNG custody transfer is readily available, however it is not yet routinely implemented. In metrology it is well known that harmonization can lead to an overall improvement in the accuracy of custody transfer systems, thereby increasing reliability in the trade of LNG.

Introduction

The global LNG custody transfer market has grown at the steady and strong pace of approximately 5 % over the last decade and a half [1–8] as economies seek to match supply and demand globally. A primary mechanism of natural gas transport is through pipelines while LNG is transported with LNG carriers from regions of production to regions of consumption. The rise of transported volume of LNG was predicted over the past two decades [9, 10]. LNG accounted for nearly 59 % of all globally traded natural gas in 2023 [11] and is projected to remain of importance for future energy demand in the upcoming decades [12, 13].

LNG transport takes place when an LNG carrier is being loaded at an LNG production plant and unloads at an LNG importing terminal. Custody transfer takes place when the cargo changes owner. LNG is customarily traded following the practices set out in the custody transfer handbook (CTH) of the international group of LNG importers (GIIGNL) [14]. LNG trade is based on the measurement of transferred energy, and comprises the determination of the volume of the carriers’ cargo tank, the LNG density, and the gross calorific value. Billing then takes place based on the price of the transferred energy. After the LNG is received by an LNG importing terminal, the bulk of LNG is regasified and, following treatments to ensure the required gas quality, distributed through the natural gas grid.

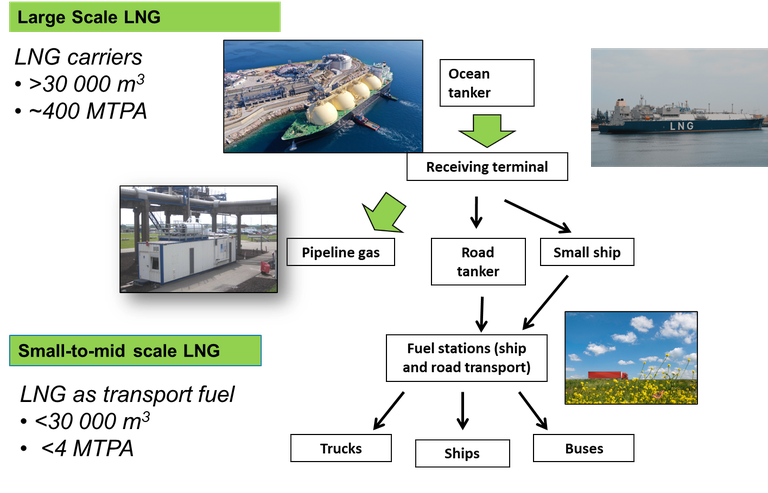

Over the past two decades, the use of LNG as fuel for ships and trucks has evolved, driven by the goal set by governments and industry of transitioning to cleaner transportation fuels. Reduced emitted CO2 and sulfuric compounds, and noise reduction from LNG engines in comparison to engines using traditional fuels are commonly mentioned advantages towards cleaner transportation [15]. When transitioning further towards liquefied methane from biomethane or liquefied biogas (bio-LNG), fully decarbonized transportation is envisioned as a readily available solution [16]. Figure 1 shows the transport routes when a carrier containing LNG unloads its cargo at the receiving terminal. When the LNG is received, it is transported either through the natural gas grid (after regasification), or used as a fuel. In the latter application, the LNG is transported through bunkering ships and road tankers. The LNG is then supplied by the bunkering ship to LNG fuelled ships or supplied by the road tanker to LNG refuelling stations, which in turn dispense the LNG to LNG fuelled trucks and buses. The bulk of the LNG is transported into the natural gas grid and a relatively small amount is used as a fuel. Global trade in LNG stood at about 400 megatons per annum (MTPA), which equates to about 500 billion m3 of natural gas at standard conditions (at 15 ºC and 1013 mbar), or 59 % of all globally traded natural gas.

Figure 1: Schematic of LNG transport routes for large scale and small-to-mid scale and its end-uses, including estimates of traded LNG amounts. This figure used pictures from Shutterstock (2135901935 & 2329479395) and from the 16ENG09 LNGIII project (EURAMET website). Estimates are based on the GIIGNL 2023 annual report [8].

While custody transfer at the large scale requires volume measurements, those at the small-to-mid scale are typically mass based. The LNG-density can be used to convert a volume measurement to a mass measurement, or vice-versa, and since LNG-density is determined in the practices set out in the large scale transport of LNG there is a natural potential overlap in measurement methodologies between the small-to-mid scale and the large scale. This in turn can be exploited to harmonize small-to-mid-scale LNG custody transfer measurement methods with those used at the large scale.

In this article, custody transfer measurement at the large scale and at the small-to-mid scale will be presented followed by possible pathways to increase reliability in the trade of LNG.

Large scale LNG custody transfer

Large scale LNG is customarily traded following the GIIGNL CTH, in which the following formula is employed [14]:

![]() (1)

(1)

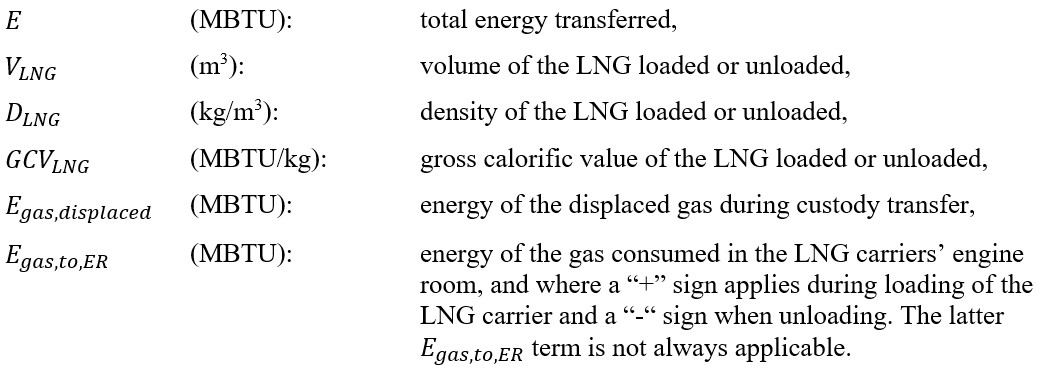

where:

Note that 1 BTU approximately equals 1.055 kJ and the prefix M indicates 1 × 106.

The GIIGNL CTH [14] provides a systematic overview of customarily employed methods for the determination of VLNG, DLNG, GCVLNG, Egas,displaced, and Egas,to,ER.

VLNG is traditionally determined from the gauge tables where the LNG level measurement is related to the corresponding volume of the carriers’ cargo tank.

DLNG is typically determined from the LNG composition and an equation-of-state in which the composition and temperature measurements are combined to compute the density.

GCVLNG is also computed from the LNG composition measurement and applicable documentary standards such as ISO 6976 [17]. The LNG composition measurement is typically performed by taking samples from the LNG stream, when in liquid phase, their vaporization, and subsequent composition measurement in the gas phase by gas analysers. The GIIGNL CTH refers to ISO 8943 [18] for the sampling processes.

Egas,displaced in turn is determined from , the carriers’ tank pressure and temperature, and the gross calorific value of the gas. Egas,displaced is typically less than 1 % of E.

Egas,to,ER, which is not always applicable, is determined from the amount of consumed gas as determined by flow meters or from an agreed formula between buyer and seller. It is typically small with respect to E.

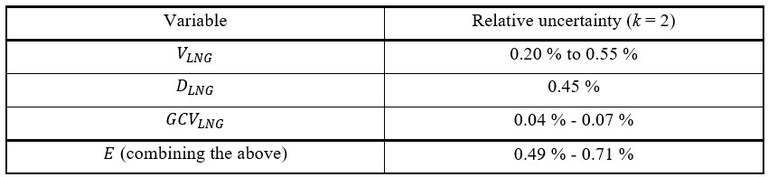

Thus the determination of E requires measurements of LNG volume, density, composition, temperature, and pressure and the employment of an equation-of-state. The GIIGNL CTH provides a combined measurement uncertainty statement from relative uncertainties on VLNG, DLNG, GCVLNG, which is reprocessed in Table 1 below (for a coverage factor of 2, indicating a coverage probability of 95 %). It is noted in the GIIGNL CTH that the uncertainty budgets should be determined for each (un)loading (of the LNG carrier).

Table 1: Combined relative measurement uncertainty statement on total LNG energy transferred, or E (Table reprocessed from the GIIGNL CTH [14]).

Small-to-mid scale LNG custody transfer

The GIIGNL CTH describes that the large scale custody transfer methods, and corresponding measurements, are applicable to the loading and unloading of small scale vessels in a similar fashion to the large scale. Small scale vessels are defined as having cargo sizes ranging between 200 m³ and 30 000 m³. At the same time the GIIGNL CTH states that usage of in-line flow meters for determining the volume or mass transferred may be a more practical option against the background of several completed European LNG metrology research projects [15, 19-20].

In-line flow meters used in LNG custody transfer are typically based on the Coriolis force principle, or on the ultrasonic transit time difference principle, both effects created from the flow through the flow meter. Coriolis flow meters used in LNG applications have sizes starting from about 25 mm pipe diameter and, by nature of their measurement principle, measure mass flow rate (unit: [t/h]) directly. Ultrasonic flow meters used in LNG applications have sizes starting from about 80 mm pipe diameter and can cover pipe diameters as large as 1300 mm, which occur at LNG terminals [21]. Ultrasonic LNG flow meters, by nature of their measurement principle, measure volume flow rate (unit: [m3/h]).

At LNG fuel dispensing stations custody transfer takes place based on the LNG mass transferred which is typically determined by Coriolis LNG flow meter measurement. Within OIML R 117 [22], LNG measuring systems fall within accuracy class 1.5. When using a flow meter, it is required to have a maximum permissible error (MPE) of 1.0 %. Over the past one-and-a-half decades, capability was developed to calibrate LNG flow meters directly with LNG with uncertainties as low as 0.17 % (coverage probability of 95 %) on mass flow rate.

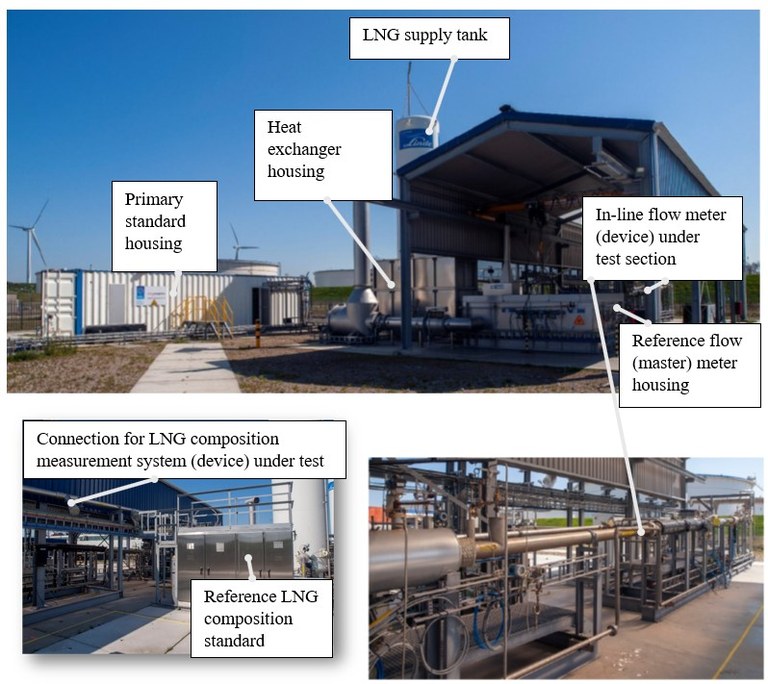

Figure 2 shows VSL’s calibration and test facility for LNG quantity and LNG composition measurement systems. The facility is fully traceable to the SI units of measurement. At this facility, research was performed into Coriolis LNG flow meter errors suggesting that lower accuracy classes for the LNG in-line flow meter can be achieved [23-26]. It can then be seen that usage of a Coriolis LNG flow meter for LNG custody transfer based on mass can improve the overall accuracy of the system it operates in. It is noted that the OIML R 117 accuracy class for fuel dispensers, (un)loading ships, rail and road tankers, fuelling aircraft, and bunkering measuring systems is at 0.5, which requires the flow meter to have an MPE of 0.3 % to 0.5 %. It can further be seen that calibration of ultrasonic flow meters directly on LNG, enables a direct link to be established with the SI units of measurement, which in turn enables an alternative method to determine VLNG (c.f., equation (1)).

Thus, several opportunities arise to harmonize small-to-mid-scale and large scale LNG measurements.

Figure 2: VSL’s calibration and test facility for LNG quantity and LNG composition measurement systems, which is fully traceable to the SI units of measurement. Outline of several main components (top, reprocessed from [21]), LNG composition measurement system (device) under test connection point (lower left, reprocessed from [25]), zoom-in of in-line flow meter test section (lower right, reprocessed from [27]).

Harmonizing mass and volume LNG custody transfer measurements

Substituting

![]()

into equation (1), the custody transfer equation is written as [25]:

![]()

where:

![]() = mass of LNG loaded or unloaded.

= mass of LNG loaded or unloaded.

Other variables are defined with equation (1).

Thus, conceptually, employment of a Coriolis LNG flow meter at the large custody transfer scale would enable comparison of this independent LNG measurement method with the traditional method. If both the LNG Coriolis flow meter and the traditional volume determination of the LNG carriers’ cargo are traceable to the SI units of measurement, one can improve the reliability in the trade of LNG. This means that independently measured values on the LNG mass (mLNG – from the Coriolis LNG flow meter) or (VLNG x DLNG - from the customary method) are in agreement with each other and that redundancy of measurement systems ensures robust custody transfer.

In a practical sense, employment of Coriolis LNG flow meters at the large scale custody transfer is not as trivial as it may seem. Coriolis LNG flow meters are limited in their size, due to (limiting) cost increases and/or due to physical constraints. Further, calibration capability on LNG is limited in its range (to the best knowledge of the authors, at the time of writing, at about 150 m3/h or ±70 t/h [25]).

Alternatively, flow meter calibrations can be performed on water at larger flow rates. However, strictly speaking the transferability of the calibration on water result to LNG conditions comes with a thus far unknown, additional error (which may be sufficiently small given the accuracy class needed). In metrological terms, this additional, unknown error renders an uncertainty source that is difficult to quantify, and, by that fact, not supporting reliability in the trade of LNG. This can be solved by a so-called bootstrapping scheme. This would involve direct flow calibration of a flow meter on LNG, which establishes the direct link with the SI units of measurement at relatively small flow rates. Then, the calibration is upscaled to larger flow rates. This can entail parallelizing Coriolis LNG flow meters calibrated on LNG to measure larger flow rates and/or establishing LNG flow calibration relationships between smaller sized and larger sized Coriolis LNG flow meters. A 150 mm diameter Coriolis LNG flow meter has a stated maximum flow rate at about 500 t/h, which is about seven times the 70 t/h maximum flow rate for which direct calibration capability on LNG exists, and which is nearly the typical maximum flow rate for a 50 mm diameter sized Coriolis LNG flow meter.

A “back-of-the-envelope” computation of a 30 000 m3 vessel, which demarcates the small scale from larger scales, of which unloading takes place in about 6 hours suggests that the flow rate would be at about 2300 t/h. This flow rate could then be measured by five parallelized 150 mm diameter Coriolis LNG flow meters. Comparison of independent measurement methods can also be performed by downscaling the large scale measurements for volume and density determination to the smaller scale, for instance by assessing the performance of LNG composition measurement systems and resulting LNG-density values (DLNG) concurrently with the LNG calibrations of dedicated LNG-densitometers and Coriolis LNG flow meters at the small scale.

Ultrasonic LNG flow meters are customarily used during LNG transport measurements at the large scale for allocation and non-fiscal measurements [21]. Their calibration can be performed directly on LNG to determine VLNG and then, similar to as described above, one can improve the reliability in the trade of LNG by comparing independent measurements from the ultrasonic LNG flow meter and from the customary method. Now, the practical challenges are:

- restricted LNG flow meter calibration capability (ultrasonic flow meters used in LNG applications have sizes starting from about 80 mm pipe diameter while direct calibration capability on LNG can cover up to typically 50 mm pipe diameter);

- less data is available on ultrasonic LNG flow meters’ achievable accuracy on LNG; and

- less data is available on the relationship between their calibration on water and their calibration on LNG (see, [23, 24] for some indications).

Yet, in a similar fashion as for Coriolis LNG flow meters, a bootstrapping scheme can be developed for ultrasonic LNG flow meters to transfer directly traceable small-to-mid scale LNG calibrations to large scale LNG calibrations while maintaining full traceability to the SI units of measurement. Given the current install base of ultrasonic LNG flow meters at LNG terminals, it can be envisioned that in the future ultrasonic LNG flow meters are customarily used, in conjunction with, or as an alternative to, the customary volume determination of LNG energy transferred (c.f., equation (1)).

Further possibilities to improve accuracy from comparison of independent LNG measurement methods exist. For instance, the volume of LNG can be determined from Coriolis LNG flow meters through the calibration of their mass and density measurements, which is then used to calibrate ultrasonic LNG flow meters in the bootstrapping procedure while maintaining a complete and full link to the SI units of measurement.

Sophisticated methods exist in metrology to reduce overall measurement uncertainty:

- When two in-line flow meters are placed in series, which are based on different (independent) measurement principles, overall measurement uncertainty can be reduced to a value lower than the lowest uncertainty value of the two meters in series [28].

- Reduction of uncertainty from uncorrelated uncertainty sources when parallelizing flow meters (as part of bootstrapping schemes) with respect to using a single flow meter instead [29].

- Harmonizing of measurement values obtained from independent SI-traceability chains involving corrections to the reference value as obtained from intercomparisons between laboratories [30].

It appears that the comparison of different, independent measurement methods for LNG custody transfer, at all scales, can reduce the overall measurement uncertainty, thereby improving the accuracy. Furthermore, these methods are readily available which enables reliability in the trade of LNG to be increased.

Conclusions

LNG is a significant source of energy supply globally and its trade continues to grow and diversify, in terms of its end-uses, global shipping pathways, and versatility when transitioning towards decarbonized energy from bio-LNG.

Alongside the steady growth in LNG trade in the past decades, new LNG measurement capabilities have matured. These include calibration capabilities which establish a direct link to the SI units of measurement on LNG, and as applicable during LNG custody transfer process conditions.

Bootstrapping schemes can be adopted to transfer fully traceable small-scale calibrations on LNG to the scale needed. Verifying improved accuracy classes of in-line flow meters and composition measurement systems seems attainable. Furthermore, sophisticated metrology practices can be adopted to reduce overall measurement uncertainty during LNG custody transfer by harmonizing independent measurement techniques. In particular, mass based and volume based measurements can be harmonized by combining small-to-mid scale and large scale LNG custody transfer measurements. Financial risk to either the exporter or importer of LNG can then significantly be reduced. This stimulates reliability in LNG trade as desired from the continued significance of the global trade in LNG.

Acknowledgements

Ara Abdulrahman at VSL is acknowledged for his careful review of the initial manuscript.

References

[1-8] International Group of Liquefied Natural Gas Importers (GIIGNL), 2010, 2011, 2013, 2014, 2015, 2021, 2022, 2023 annual reports.

[9] International Energy Agency, World Energy Outlook 2010.

[10] BP, BP Energy Outlook 2030, 2011.

[11] Energy Institute, Statistical Review of World Energy, 73rd edition, 2024.

[12] BP, BP Energy Outlook, 2023 edition.

[13] International Energy Agency, World Energy Outlook 2023.

[14] International Group of Liquefied Natural Gas Importers (GIIGNL), LNG custody transfer handbook, 6th edition: 2021 (Paris, GIIGNL).

[15] Publishable Summary for 16ENG09 LNGIII, Metrological support for LNG and LBG as transport fuel, EURAMET, Link, 27 June 2024.

[16] DNV, 2023, Energy Transition Outlook 2023, Maritime Forecast to 2050. Link, 27 June 2024.

[17] ISO 6976:2016, Natural gas — Calculation of calorific values, density, relative density and Wobbe indices from composition.

[18] ISO 8943:2007 Refrigerated light hydrocarbon fluids — Sampling of liquefied natural gas — Continuous and intermittent methods.

[19] Publishable Summary for ENG03 LNG, Metrology for Liquefied Natural Gas, EURAMET, Link, 3 July 2024.

[20] Publishable Summary for ENG60 LNGII, Metrological support for LNG custody transfer and transport fuel applications, EURAMET, Link, 3 July 2024.

[21] Final report 16ENG09 LNGIII, Metrological support for LNG and LBG as transport fuel, EURAMET, Link, 27 June 2024.

[22] OIML R 117 Dynamic measuring systems for liquids other than water. Part 1: Metrological and technical requirements, 2019.

[23] Schakel, M., Liquid nitrogen calibrations of industry-standard LNG flow meters used in LNG custody transfer, 2019, Link, 3 July 2024.

[24] Kenbar, A., Schakel, M., Influence of flow disturbances on the performance of industry-standard LNG flow meters, 2021, Flow Measurement and Instrumentation 77, 101871, https://doi.org/10.1016/j.flowmeasinst.2020.101871.

[25] Smits, F.M., Financial risks in dynamic LNG measurement, Global LNG Bunkering Experience, 2021.

[26] Gugole, F., Schakel, M.D., Druzhkov, A., Brugman, M., Assessment of alternative fluid calibration to estimate traceable liquefied hydrogen flow measurement uncertainty, 2024, International Journal of Hydrogen Energy 77, 1056–1065, https://doi.org/10.1016/j.ijhydene.2024.06.177.

[27] Standiford, D., Calibration is the key, 2021, LNG Industry.

[28] Wilson, A., Stockton, P., Steven, R., Data Reconciliation in Microcosm – Reducing DP Meter Uncertainty, North Sea Flow Measurement Workshop, 2019.

[29] ISO 5168:2005, Measurement of fluid flow — Procedures for the evaluation of uncertainties.

[30] Dopheide, D., Mickan, B., Kramer, R., Hotze, H.-J., van der Beek, M., Blom, G., Vallet, J.-P., Gorieu, O., Final report on the CIPM Key Comparisons for Natural Gas at High-Pressure Conducted in November / December 2004 CCM.FF-5.a, BIPM Key Comparison Database, CCM.FF-K5.a, 2005.